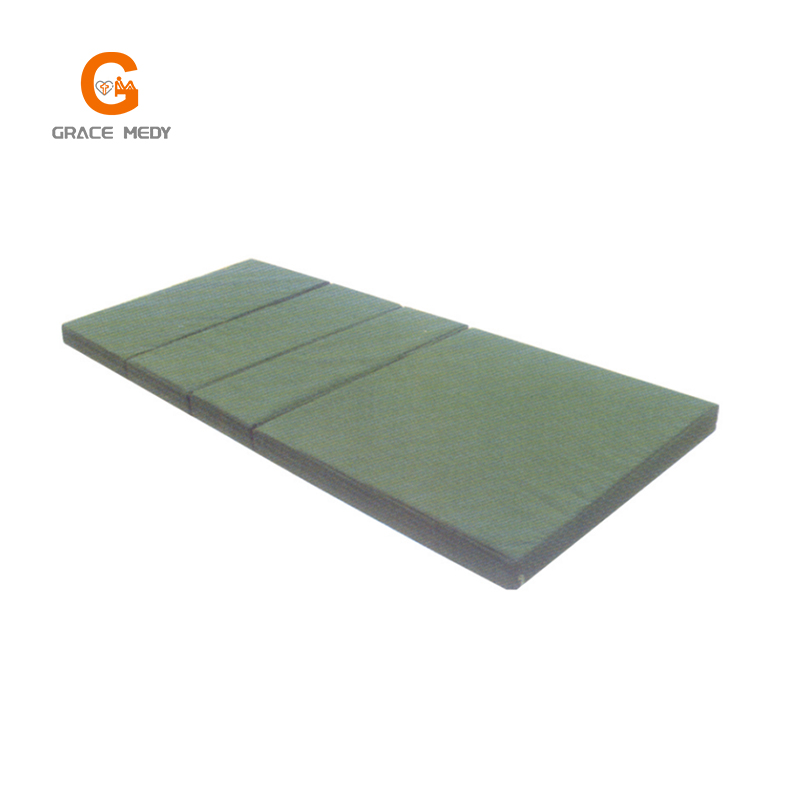

Did you know there is a mattress that is a fireproof mattress?

It is made of fireproof sponge, fireproof sponge is also called flame-retardant sponge, fireproof cotton, flame-retardant cotton, generally it is a fireproof material synthesized by adding flame retardants to various polyurethanes, mainly used in furniture manufacturing, massage equipment manufacturing, baby carriages Manufacturing, decoration, car accessories, wall sound absorption, insulation pipes, fire doors and fire shutters, etc.

Imported flame retardants, melamine and other additives are used to directly improve the flame retardant and fireproof performance of the product. It can absorb heat and decompose into non-flammable substances at or near the ignition temperature; it can react with foam combustion products to produce non-flammable substances; it can delay burning and block smoke to cause self-extinguishing of the burning part. White smoke is released during combustion, reducing environmental pollution and emission of harmful substances.

The fireproof sponge uses imported flame retardants, which can effectively reduce the burning time, delay burning, block smoke and cause the fire parts to self-extinguish. Usually the simplest test method is that the sponge will automatically extinguish within 6 seconds after leaving the fire source.

Fireproof sponge, whose chemical name is polyurethane foam material, is divided into two types: soft foam (mainly used for furniture) and hard foam (mainly used for heat preservation). The main raw materials are fire retardant, isocyanate, polyethers, polyols, etc., and the auxiliary raw materials include a small amount of freon, water, etc.

Fire resistance: When the sponge is burning, it will not produce an open flame.

Water resistance: closed cell structure, good water absorption performance.

Corrosion resistance: resistant to seawater, oil, acid, alkali and other chemical corrosion, antibacterial, non-toxic, tasteless, and pollution-free.

Processability: No joints, and easy to process such as hot pressing, cutting, gluing, laminating, etc.

Anti-vibration: High resilience and tensile strength, strong toughness, and good shock-proof/cushioning performance.

Thermal insulation: heat insulation, excellent thermal insulation, cold protection and low temperature performance, and can withstand severe cold and exposure.

Sound insulation: airtight cells, good sound insulation.

Sponge is divided into three types: thin, medium and thick, among which there are soft and hard points:

1. Thin (1.0mm-8mm), used in packaging industry;

2. Medium (8mm-30mm), used in furniture and massage equipment industries;

3. Thick (over 30mm), used in furniture and sofa industry.

Fireproof sponge hardness:

20-35°, soft sponge

45-60°, neutral sponge

60-70°, hard sponge

Above 70°, add hard sponge

Because of its characteristics of heat preservation, heat insulation, sound absorption, shock absorption, flame retardant, anti-static, and good air permeability, fireproof sponges are involved in various industries, including automobile industry, pharmaceutical industry, cosmetics industry, special packaging manufacturing industry and high-end furniture. Manufacturing etc.

Post time: Jun-26-2023